Superfund Research Program

Modeling and Field Tests Yield Promising Results for Aquifer Clean Up

View Research Brief as PDF(721KB)

Release Date: 03/03/2021

![]() subscribe/listen via iTunes, download(7.0MB), Transcript(91KB)

subscribe/listen via iTunes, download(7.0MB), Transcript(91KB)

NIEHS Superfund Research Program (SRP) grantees have developed novel, slow-release oxidant-paraffin candles that dissolve and degrade chlorinated contaminants in underground aquifers. The grant recipient, small business AirLift Environmental, worked with partners at the University of Nebraska-Lincoln (UNL) to optimize this groundwater clean-up method and demonstrated its effectiveness in a field study.

When the oxidant-infused candles are lowered into groundwater, they slowly dissolve, releasing molecules that degrade chlorinated contaminants into harmless carbon dioxide gas. Their technology works quickly, as oxidant candles have been shown to reduce up to 99% of contaminant concentrations within 9 months of installation compared to standard pump and treat practices that can take several decades to decontaminate water.

Airlift Environmental President Mark Christenson stated the candles could offer significant cost savings. Through a project funded by the Environmental Protection Agency, he estimated that treating approximately two acres of land contaminated with chlorinated chemicals would cost about $20,000. By contrast, a 2008 estimate by the Department of Defense put clean-up costs with traditional pump and treat methods between $1 and $5 million per acre.

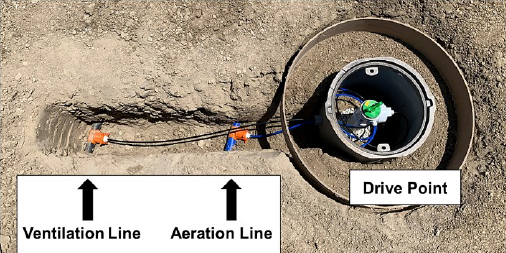

The researchers created their novel aeration system by affixing air pumps to release bubbles at the base of the candles. Bubbling air beneath each oxidant candle creates a circulation system within the groundwater that allows for more even and prolonged spreading of the oxidant throughout the contaminated aquifer.

By combining an airlift pump with a slow-release oxidant, the tool overcomes many of the challenges faced by traditional groundwater clean-up approaches that rely on highly concentrated liquid oxidants, which require specialized equipment and have safety concerns for handling. The slow-release candles also provide longer-term treatment.

Optimizing A Reliable Method

Site conditions differ and can affect how the oxidant released from the candles behaves and how far it spreads, known as the radius of influence. Defining this radius helps to avoid gaps in oxidant coverage and ensure proper spacing in the field. This is an important step to accurately estimate the cost of full-scale remediation projects.

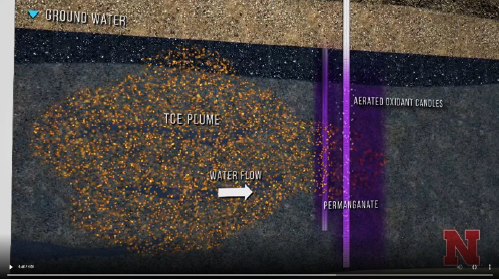

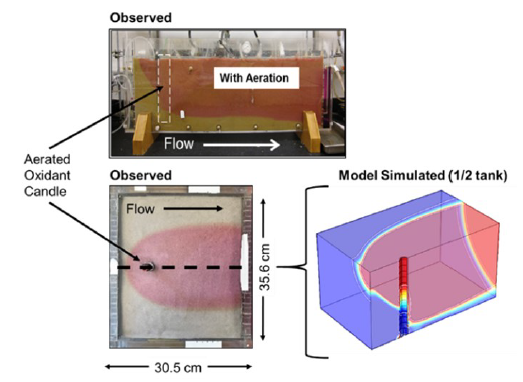

The AirLift and UNL team conducted laboratory flow tank experiments. They developed numerical modeling approaches to identify factors controlling the radius of influence of oxidizing compound potassium permanganate.

To simulate field conditions, the researchers constructed custom flow tanks with tubes to hold the candles in soil. Then they measured how the oxidant moved and spread over time under different aeration and water flow conditions by taking pictures and comparing results to simulated results from their model. Using flow and transport numerical modeling, they evaluated the influence of each condition on oxidant distribution alone and in combination.

Results from the flow-tanks showed permanganate spreading and radius of influence increased with aeration and decreased with water flow. The flow and transport model successfully reproduced observed results by mimicking the movements of permanganate under different conditions, which is useful for scaling up to the field.

The team then validated their findings in three separate field studies where the placement and spacing of drive points containing the aerated candles were tailored to water flow considerations. Contaminants at these sites included chlorinated chemicals like trichloroethylene (TCE), a volatile organic compound commonly used as an industrial degreaser, and other compounds found in petroleum products.

Results showed that contaminant concentrations decreased 50-99% within 6 to 9 months after installation. According to the researchers, these results demonstrate that their technology could effectively remediate groundwater and that their modeling and flow tank predictions were accurate.

Potential for Broad Impact

According to the team, the ability to reload the oxidant candles as needed allows for uninterrupted treatment for months to years. Longer treatment times can help the oxidant penetrate further and reduce the potential for contaminants to seep back into treated areas.

By determining the area slow-release oxidants can affect under a variety of site-specific conditions, the cost of full-scale remediation projects can be more accurately determined for any given area. The computational model also adds an additional layer of efficiency when scaling up to field sites by identifying optimal candle spacing to avoid over-treating.

The Nebraska Department of Environment and Energy approved the use of aerated oxidant candles so they can be installed in multiple locations across the state. Given the state is home to much of the Ogallala Aquifer, one of the largest aquifers in the world, this advancement in environmental technology has the potential to affect many communities.

For More Information Contact:

Mark Christenson

Airlift Environmental, LLC

1421 SW 36th Street

Lincoln, Nebraska 68522

Phone: 402-617-0434

Email: mark@airliftenvironmental.com

Steve Comfort

University of Nebraska

School of Natural Resources

205 Kiesselbach Crop Research Laboratory

Lincoln, Nebraska 68583-0915

Phone: 402-472-1502

Email: scomfort1@unl.edu

To learn more about this research, please refer to the following sources:

- Kambhu A, Li Y, Gilmore T, Comfort S. 2021. Modeling the release and spreading of permanganate from aerated slow-release oxidants in a laboratory flow tank. J Hazard Mater 403:12. doi:10.1016/j.jhazmat.2020.123719 PMID:33264895

- Reece J, Christenson M, Kambhu A, Li Y, Harris CE, Comfort S. 2020. Remediating contaminated groundwater with an aerated, direct-push, oxidant delivery system. Water (Basel) 12:20. doi:10.3390/w12123383

To receive monthly mailings of the Research Briefs, send your email address to srpinfo@niehs.nih.gov.